Commercial Distillation Equipment

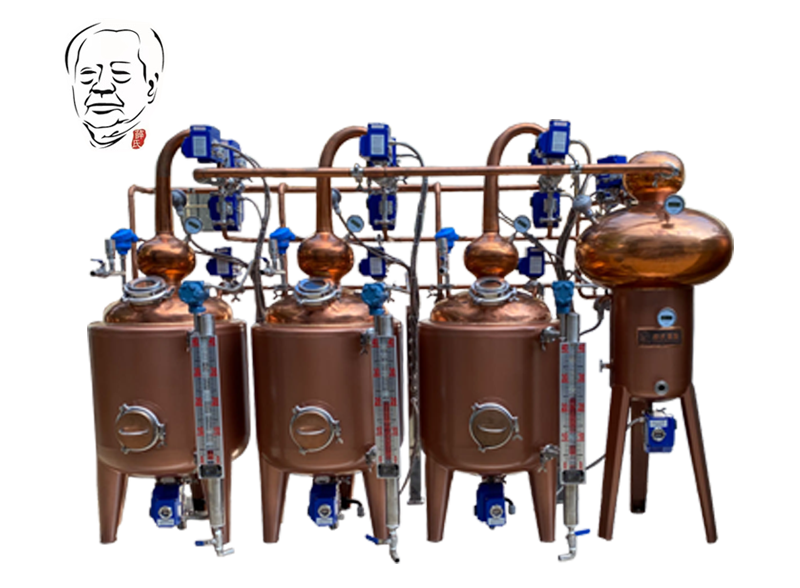

3000L Triple Pot Still alcohol Distillation Equipment

This distiller is for commercial us. Its advantage is continuous distillation, elevated alcohol concentration.

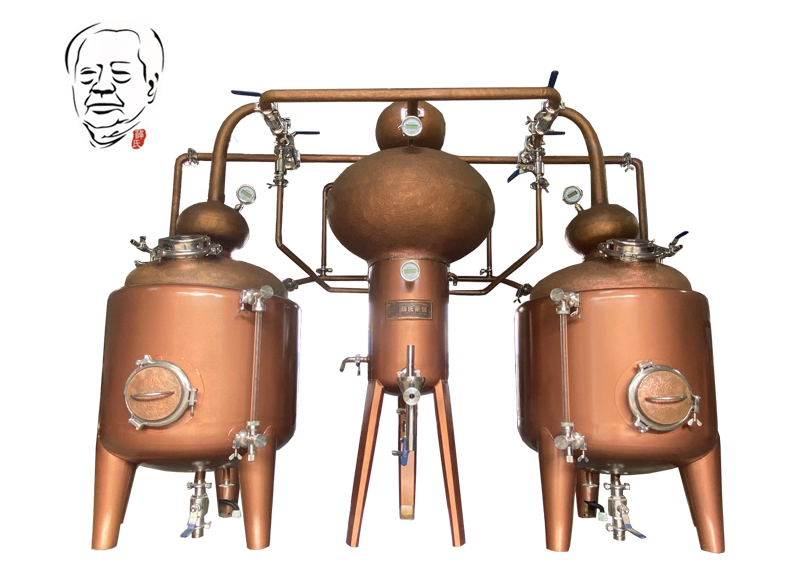

1000L Small Size Dual Pot Still Distillation Equipment

50L stills with automatic or manual control, easy to operation. It has been patented, and it’s the ideal distiller for liquor.

500L Triple Pot Still Continuous Brandy Distiller

500L commercial distillation equipment for high quality alcohol production. it’s good for distilling brandy.

50L Red Copper Hand Hammered Pot Still Distiller

The pot stills are made of pure red copper and with hand hammered surface. Manufactured to customization.

Advantage Of Xue’s Distillation Equipment

Maximization of material wine by multi pot still system

The basic function of pot still is to collect alcohol and some original ingredients from material wine. Besides it generates some of the trace ingredients by chemical reactions during the process of distillation. Meanwhile it decreases the content of unpleasant or harmful substances.

Repeated distillation processes enable maximization of these functions. So the product alcohol has enriched aromas multi level flavor that cannot be matched by traditional pot still or tower still.

The multiple pot stills operate in turn, seamlessly transferring distillate from pot to pot, allowing for continuous production batches that streamline your distillery’s efficiency and maximization to material wine.

Precise cutting to the head, heart and tail by innovative pipeline design

With dedicated outlet pipes for the head, heart, and tail in each pot still, our distiller ensures a precise separation of each component. The head, heart, and tail flow through their dedicated pipes, eliminating any unwanted mixing. This innovative design eliminates pipeline wastage, maximizing utility and product alcohol purity. After the head is cut, the heart, the true essence of your spirits, is collected directly as the final product. The tail, on the other hand, is cleverly recycled by downstream pot still, adding depth and character to the next batch.

Saving 70% Energy with Recycling Heat

The material wine and distillate exchange heat energy in the heat exchanger, the distillate releases heat energy to be cooled, and the material wine obtains heat energy to be preheated, which makes the distillation process consume less heat energy and takes less time. With this innovative design, an impressive 70% more energy saving is obtained compared to traditional Charente distillers.

Xues’ Distillation Equipment Cases Show

15

Years Of Experience

50+

Type Of Equipments

200+

Customers